Главная

страница

Сведения об авторах

The Thermo-Compactor-Desiccator®

(TCD®)

MUNICIPAL SOLID WASTE TREATMENT PLANT

Shahverdian A., System Evergreen AG, Lugano, Switzerland

Introduction

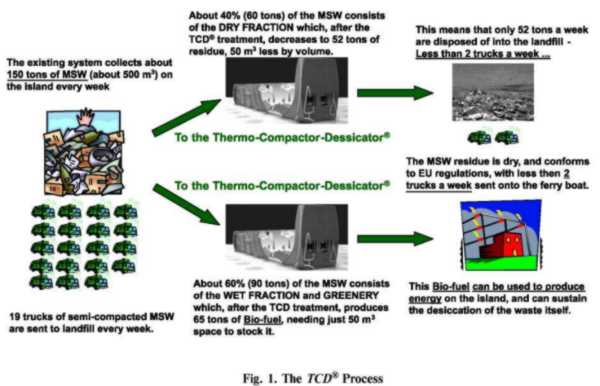

The TCD® Process is an MSW

treatment that heats and compresses MSW, giving an end-product

consisting of a dense solid which is inert, sterile, and

combustible; and which is up to 1/12th of its original volume;

plus water and air which contain just fractions of allowable

quantities of undesirable substances.

The TCD®

Process

The TCD® Process compresses the

MSW, then heats it to under 180 °C while simultaneously

compressing it further. The raw garbage is thus desiccated and

compacted, producing a dense solid, as well as water and air that

are virtually clean.

At this point, the garbage has been transformed into a solid

substance with completely different physical, chemical and

biological properties — it is sterile — and it can be used as

an RDF. The dense solid is up to 1/12th of the volume and up to

70% of the weight of the original garbage (fig. 1).

TCD® PROCESS APPLIED TO AN ISLAND

The first results are taken from test

analyses made by the University of Pavia, the Polytechnic of

Milan, and SGS (Societe Generale de Surveillance).

The TCD® Process offers 8 real

competitive advantages:

— Lower emissions into the atmosphere and ground water

— Reduced volumes

— Low oxidation index — IR — IRP IRR, no stench

— Low OMEI (Organic Matter Evolution Index)

— Low COD & BOD

— Great opportunity to prepare good RDF with the organic part

of MSW

— Biological stability and maturity

— Biochemical stability.

The TCD®

Plant

The Plant consists of a hydraulic press, the «Cage», which is

the heart of the system and which is where the garbage is heated

by a circulating thermo-vectoral liquid and compacted. Auxiliary

equipment mainly consists of a Pre-sorter (where necessary), a

boiler for the thermo-vectoral liquid, a bio-filter for the

vapours resulting from the desiccation process and a computer

station which monitors the Plant's processing and maintenance

requirements, and communicates by satellite with headquarters.

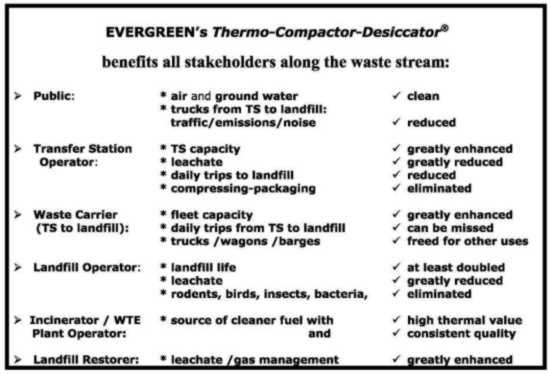

The TCD® is presently available in

modular form which can process 50/100 tons of garbage per day.

Placed at a transit station, it completely transforms the

logistics along the entire waste stream, with many important

benefits for all stakeholders (fig. 2).

Fig. 2. Benefits for all stakeholders

A battery of 4 modules processing 200/400 tpd require only 800 m2. The system's flexibility also makes it an excellent producer of RDF with different specifications. The table illustrates the TCD® and other processes.

TCD® сompared with other processes

| Type of Waste | Process |

Cost, euro/ton |

Volume Reduction |

| Dry Fraction | Incinerator |

150-200 |

5:1 |

Landfill |

70-150 |

3:1 |

|

TCD® |

15-25 |

10:1- 14:1 |

|

| No Selection | Incinerator |

150-200 |

5:1 |

Landfill |

70-150 |

3:1 |

|

TCD® |

15-25 |

10:1- 14:1 |

|

| Wet Fraction | Incinerator |

70-150 |

5:1 |

Landfill |

45 |

1:1 |

|

Compost |

60 Operation + 40 Equity |

1:1 |

|

TCD® |

30 |

10:1- 14:1 |

Shahverdian Abel, System Evergreen AG, Strada di Gandria 33, CH-6976 Lugano, Switzerland. Tel. (91) 973-20-90, fax (91) 973-20-99. E-mail, http://www.evergreen.eu

© Независимое агентство экологической информации

Последние изменения внесены 10.07.07