Ãëàâíàÿ

ñòðàíèöà

Ñâåäåíèÿ

îá àâòîðàõ

Establishment of a Management System for PCB-contaminated Electrical Equipment. Example: Republic of Macedonia

Barlakoska L., Bergel H., Envio Recycling GmbH & Co. KG, Dortmund, Germany

Introduction

The Republic of Macedonia signed the Stockholm Convention on 23rd of May 2001 and ratified it on 19th of March 2004. In the frame of the Ministry of Environment and Physical Planning, a POPs Unit was established in order to implement the provisions of the Stockholm Convention. According to the Government Decision adopted on its 9th session from 24th of January 2005, the Ministry of Environment and Physical Planning/POPs Unit is responsible for POPs management on national level. The National Implementation Plan (NIP) on Reduction & Elimination of Persistent Organic Pollutants in the Republic of Macedonia, after two years of preparation, was completed in 2004 and submitted to the Stockholm Convention on 2nd of September 2005. It assessed the situation in the country regarding POPs and identified the actions to be undertaken for fulfilling the requirements of the Stockholm Convention.

The Ministry of Environment and Physical Planning in 2007 began the Public Private Partnership (PPP) Project — Establishment of a management system for PCB-contaminated electrical equipment in the Republic of Macedonia together with the «Deutsche Gesellschaft fur Technische Zusammenarbeit» (GTZ) and Envio Recycling GmbH & Co. KG with financial assistance of the German Federal Ministry of Economic Cooperation (BMZ). The aim of the project was assisting the Republic of Macedonia to comply with the obligations of the Stockholm Convention. The specific objectives were: i) assisting the Ministry of Environment and Physical Planning in establishment of a management system for safe disposal of PCBs and PCB-containing equipment; ii) assisting the country in phasing out PCB-equipment from selected demonstration areas.

1. Polychlorinated biphenyls

The polychlorinated biphenyls (PCBs) are a class of 209 congeners with different chlorine content, physic-chemical properties, applications and names. They are man-made materials with two major sources — commercial production and by-product in combustion processes as thermodynamically stable compounds.

PCB was commercially produced since the 1930s and is severely restricted since 1980. The total world-wide production reaches 1.5 million tons. Since May 2004, the Stockholm Convention bans the PCB as one of the persistent organic pollutants (POPs). The PCB is proved as persistent, toxic, and volatile; it's also bioaccumulative, lipophilic and can be transported at long distances.

2. The process of establishing a management system for PCB-contaminated electrical equipment and the methodology for samples analysis

One of the NIP's priorities is the PCB elimination. However, the lack of regulations and technical standards for handling and disposing PCB-contaminated electrical equipment has been shown to be the main obstacle. Moreover, the above mentioned facts directed the main project activities — establishment of an inventory for electrical equipment and raising awareness about the PCB-related issues. The methodology for establishment of the PCB-management system included several activities shortly elaborated below.

2.1. Kick-off meeting

The first project meeting was held in March 2007 and included representatives of the project involved parties. There was presented the need for establishing a PCB management system based on the obligations of the Stockholm Convention that Macedonia needs to fulfil.

2.2. Awareness raising program

The main aim of the awareness raising activities was to familiarize the general public with the PCBs — what are PCBs, their main applications and which health risks they pose. Informative material (flyers and leaflets) in English and Macedonian about the PCB was disseminated and the PCB issues were also popularized in the mass media — newspapers, television and radio. The International Trade Fair of Metallurgy, Electronics, Non-Metals and Build and Construction, Security and Protection — TEHNOMA was also a place for distributing information on PCB. The disseminated printed materials presented basic information about the chemical characteristics of the PCBs, their application and commercial production — amounts, producers including all the commercial names under which PCBs have been produced as well as the environmental hazards they pose. The materials also presented the project aim and objectives and its main activities. The info contact details from the involved parties were also included in order for the individuals, companies or other interested parties to get more information about the PCB-treatment technologies, the establishment of the PCB-management system in Macedonia or else.

Trainings for the representatives of the Ministry for Environment and Physical Planning, non-governmental organizations and industry were held. The trainings were focused on imparting knowledge on regulations and international treaties that govern the environmentally sound handling as well as on the technical and environmental requirements of a temporary storage for PCB-contaminated equipment and transport of PCB-contaminated materials.

A training video «Knock Out for PCBs» — Sustainable Chemical Management for an Environmentally Sound World was produced. The video presents the complete process of conducting a PCB inventory in the selected industry — from safely disconnecting the transformers from the electronic circuit, through taking samples and analyzing to finally labelling the sampled equipment. The video also clearly shows the recommended protective clothes and safe measures during the process.

2.3. Establishing an inventory for electrical equipment

A survey of PCB-contaminated electrical equipment and PCB-contaminated oil in barrels in three industrial areas was conducted. The selection was made based on the number of owned transformers and capacitors in order for the survey results to give a picture that is close to the real one of the current situation with the PCB-contaminated electrical equipment in the country. The analysis was performed by qualitative tests using Chlor-N-Oil 50 and Chlor-N-Oil 20 test kits and quantitative tests using the L2000DX Analyzer (Table 1).

Table 1

Testing materials used in the inventory

Material |

Chlor-N-Oil 50 test kits |

Chlor-N-Oil 20 test kits |

L2000DX oil reagents |

The Chlor-N-Oil 50 test kits detect the chloride level over 50 ppm and the Chlor-N-Oil 20 test kits detect the chloride level over 20 ppm. The L2000DX Analyzer offers three methods for analyzing PCB in oil — Aroclor 1242, Aroclor 1254 and Aroclor 1260. These methods have the names of the three of the several commercial PCB mixtures marketed between the 1930s and 1970s. These were widely used in industrial applications world wide.

The samples with detected level of chlorine over 50 ppm were sent to a German accredited laboratory for reanalysis with a gas chromatography method DIN EN 12766. There were two reasons for reanalyzing only the samples with above 50 ppm chloride level. The first reason is that the Chlor-N-Oil test kits are qualitative tests — the tests results only state if the sample has chlorine over or below 20, 50, 100 or 500 depending on the type of Chlor-N-Oil test kit. The precise PCB level is important for the disposal costs. The other reason is that these qualitative tests as well as the L2000DX can give «false positive». This means that if the tests detect a chloride level of 50 ppm the method of gas chromatography can detect below 50 ppm.

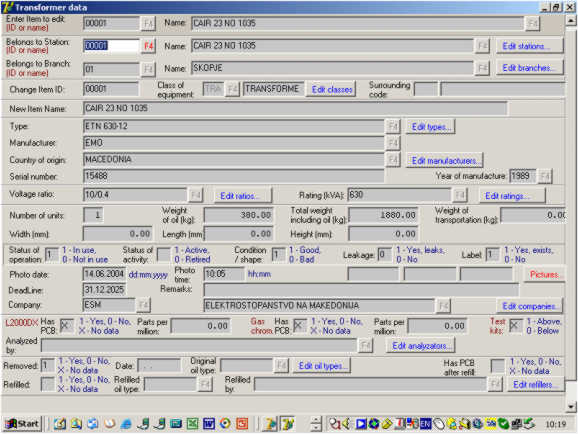

Software obtained by the POPs Unit was used for managing the inventory results. Some modifications to the software were made in order keeping more detailed records. The modifications included a few more transformer and capacitor parameters as well as a new class of PCB equipment. This was necessary for facilitating the data processing (Fig. 1).

Fig. 1. Transformer data — PCB inventory software

In April 2008 four practical trainings in the selected industrial areas were organized. The trainings had a theoretical part and a practical one. The theoretical part was focused on the following:

— Stockholm Convention — goals and obligations of the signing parties;

— POPs Unit activities;

— history, nature and applications of PCB;

— environmental and health hazardous effects of the PCB;

— PCB inventory — description;

— sampling of transformers and capacitors;

— safety measures when handling PCB-contaminated equipment.

The practical part took place at the site addressing several issues related to PCB:

— safety measures when handling PCB-contaminated equipment;

— personal and environmental safety measures;

— filling the details of the inventoried equipment in the inventory form;

— switching off the transformer prior sampling;

— performing Chlor-N-Oil quantitative PCB analysis;

— labeling the equipment.

3. Results

3.1. Inventory results

The samples were taken from 28 different locations and 901 units of transformers, 580 units of capacitors and 137 barrels/tanks with oil around the country. In total, 1 618 units of transformers, capacitors and barrels with oil were sampled with total weight of 3 452 134 kg (Table 2).

Table 2

Total sampled equipment

Location |

Equipment and oil in barrels/tanks |

||||

Total |

contaminated with over 50 ppm of PCB, kg |

||||

Units |

Solid + liquid, kg |

Solid + liquid |

Solid |

Liquid |

|

| Berovo | 8 |

7 271 |

0 |

0 |

0 |

| Bitola | 25 |

900 155 |

0 |

0 |

0 |

| Debar | 1 |

510 |

0 |

0 |

0 |

| Delcevo | 6 |

3 640 |

0 |

0 |

0 |

| Gevgelija | 6 |

7 460 |

2 900 |

2 200 |

700 |

| Gostivar | 102 |

47 147 |

6 492 |

4 605 |

1 887 |

| Kavadarci | 13 |

9 228 |

0 |

0 |

0 |

| Kicevo | 28 |

20 300 |

1 440 |

980 |

460 |

| Kochani | 9 |

18 480 |

440 |

340 |

100 |

| Kratovo | 11 |

4 973 |

0 |

0 |

0 |

| Kriva Palanka | 19 |

54 570 |

440 |

340 |

100 |

| Kumanovo | 77 |

167 980 |

41 380 |

30 401 |

10 979 |

| Makedonski Brod | 8 |

1 800 |

0 |

0 |

0 |

| Negotino | 4 |

4 360 |

0 |

0 |

0 |

| Ohrid | 48 |

37 198 |

1 600 |

1 180 |

420 |

| Prilep | 16 |

10 888 |

1 280 |

1 000 |

280 |

| Probishtip | 17 |

59 520 |

0 |

0 |

0 |

| Radovish | 3 |

2 815 |

0 |

0 |

0 |

| Resen | 17 |

16 420 |

522 |

371 |

151 |

| Shtip | 72 |

91 092 |

9 905 |

7 718 |

2 187 |

| Skopje | 677 |

974 840 |

73 583 |

51 378 |

22 205 |

| Struga | 35 |

10 040 |

1 893 |

1 336 |

557 |

| Strumica | 14 |

10 345 |

440 |

340 |

100 |

| Sveti Nikole | 6 |

3 620 |

0 |

0 |

0 |

| Tetovo | 351 |

949 230 |

67 871 |

53 122 |

14 749 |

| Valandovo | 7 |

3 400 |

0 |

0 |

0 |

| Veles | 33 |

32 032 |

1 600 |

1 180 |

420 |

| Vinica | 5 |

2 820 |

360 |

275 |

85 |

| Total | 1 618 |

3 452 134 |

212 146 |

156 766 |

55 380 |

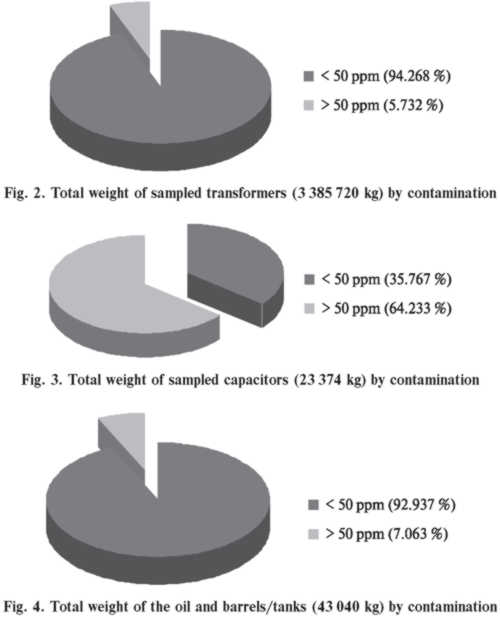

The analysis of the samples showed that 5.732 % of the transformers (based on total transformer weight), 64.233 % of the capacitors (based on total capacitor weight) and 7.063 % of the oil in barrels/ tanks (based on the total weight of the oil and barrels/tanks) are contaminated with over 50 ppm of PCB (Figs. 2, 3, 4). In total, 6.145 % of the all equipment sampled was found to be contaminated with over 50 ppm of PCB.

3.2. Comparison of the L2000DX Analyzer methods (Aroclor 1242, Aroclor 1254 and Aroclor 1260) and gas chromatography DIN EN 12766 (GC)

As previously mentioned (2.3) the samples with measured PCB levels of over 50 ppm using L2000DX were reanalyzed with gas chromatography method DIN EN 12766. Thirty six of these (33 transformer oil samples and 3 samples from oil in barrels) are compared in Table 3. In this one, the analyses results using both methods for analyzing the same samples are presented; the comparison is done by subtracting the results from both methods (Aroclor 1242 - GC, Aroclor 1254 - GC and Aroclor 1260 - GC), so that the difference is more obvious. With bold are marked the samples where the PCB level measured with L2000DX was over 50 ppm and with the gas chromatography (GC) method below 50 ppm.

Table 3

L2000DX compared to GC DIN EN 12766 using 36 oil samples

Sample |

PCB, ppm |

||||||

Aroclor 1242 |

Aroclor 1242 ? GC |

Aroclor 1254 |

Aroclor 1254 ? GC |

Aroclor 1260 |

Aroclor |

GC |

|

1 |

9.6 |

5.25 |

8.44 |

4.09 |

12.6 |

8.25 |

4.35 |

2 |

43.5 |

17.65 |

34.20 |

8.35 |

74.5 |

48.65 |

25.85 |

3 |

144.0 |

46.00 |

114.00 |

16.00 |

226.0 |

128.00 |

98.00 |

4 |

33.6 |

14.35 |

36.40 |

17.15 |

27.2 |

7.95 |

19.25 |

5 |

20.1 |

13.55 |

22.30 |

15.75 |

67.8 |

61.25 |

6.55 |

6 |

41.9 |

16.80 |

42.60 |

17.50 |

30.9 |

5.80 |

25.10 |

7 |

39.4 |

37.05 |

36.60 |

34.25 |

36.8 |

34.45 |

2.35 |

8 |

64.9 |

4.95 |

57.70 |

?2.25 |

66.4 |

6.45 |

59.95 |

9 |

32.4 |

18.55 |

34.90 |

21.05 |

93.1 |

79.25 |

13.85 |

10 |

47.7 |

14.70 |

44.10 |

11.10 |

106.0 |

73.00 |

33.00 |

11 |

107.0 |

47.50 |

101.00 |

41.50 |

80.4 |

20.90 |

59.50 |

12 |

66.8 |

?2.00 |

69.70 |

0.90 |

54.7 |

?14.10 |

68.80 |

13 |

39.8 |

13.35 |

41.20 |

14.75 |

36.7 |

10.25 |

26.45 |

14 |

217.0 |

32.85 |

178.00 |

?6.15 |

215.0 |

30.85 |

184.15 |

15 |

126.0 |

23.00 |

106.00 |

3.00 |

107.0 |

4.00 |

103.00 |

16 |

68.8 |

49.60 |

55.60 |

36.40 |

55.5 |

36.30 |

19.20 |

17 |

51.2 |

49.25 |

43.20 |

41.25 |

57.4 |

55.45 |

1.95 |

18 |

133.0 |

114.35 |

108.00 |

89.35 |

126.0 |

107.35 |

18.65 |

19 |

78.0 |

30.05 |

66.60 |

18.65 |

124.0 |

76.05 |

47.95 |

20 |

59.2 |

12.50 |

52.40 |

5.70 |

55.4 |

8.70 |

46.70 |

21 |

141.0 |

12.60 |

122.00 |

?6.40 |

108.0 |

?20.40 |

128.40 |

22 |

60.4 |

48.10 |

50.80 |

38.50 |

104.0 |

91.70 |

12.30 |

23 |

27.6 |

15.40 |

24.30 |

12.10 |

21.6 |

9.40 |

12.20 |

24 |

31.7 |

13.60 |

31.70 |

13.60 |

79.9 |

61.80 |

18.10 |

25 |

66.5 |

18.65 |

54.30 |

6.45 |

99.7 |

51.85 |

47.85 |

27 |

48.6 |

26.70 |

41.60 |

19.70 |

37.6 |

15.70 |

21.90 |

28 |

64.6 |

2.65 |

59.90 |

?2.05 |

53.3 |

?8.65 |

61.95 |

29 |

58.0 |

17.85 |

58.90 |

18.75 |

46.9 |

6.75 |

40.15 |

30 |

64.6 |

0.40 |

58.1 |

?6.10 |

59.1 |

?5.10 |

64.20 |

31 |

16.4 |

13.30 |

16.3 |

13.20 |

14.8 |

11.70 |

3.10 |

32 |

82.5 |

9.95 |

60.6 |

?11.95 |

59.4 |

?13.15 |

72.55 |

33 |

80.5 |

63.35 |

67.10 |

49.95 |

74.4 |

57.25 |

17.15 |

34 |

30.4 |

19.30 |

28.40 |

17.30 |

42.3 |

31.20 |

11.10 |

35 |

37.3 |

19.55 |

33.60 |

15.85 |

29.1 |

11.35 |

17.75 |

36 |

24.8 |

15.90 |

20.40 |

11.50 |

16.5 |

7.60 |

8.90 |

3.3. Handbook for environmentally sound management of PCB-contaminated equipment and materials

The Handbook for environmentally sound management of PCB-contaminated equipment and materials was created to serve the individuals and organizations dealing with PCB-equipment and PCB-waste. Its aim is to support the management system for recording, monitoring and disposal of PCB-contaminated transformers and capacitors in the Republic of Macedonia in an environmentally sound manner. It is primarily intended to technicians and engineers who professionally handle equipment suspected to be PCB-contaminated.

3.4. Technical description of an interim storage for PCB-containing equipment

A technical drawing of an interim storage for PCB-containing equipment was produced. It showed the main functional areas and the equipment needed for fulfilling the safety and environmental standards. The aim of the storage is to serve the country's need for safe and environmentally sound storing and preparation of the PCB-contaminated equipment before being exported abroad to certified disposal facilities. A potentially suitable location on the premises of the Rade Koncar was also identified.

4. Conclusions

The result of 6.145 % of over 50 ppm PCB-contaminated equipment is a starting point for the upcoming complete inventory in the country. The establishment of the system for management of PCB-contaminated electrical equipment was the first step towards elimination of the PCB in the country. With this inventory, the Republic of Macedonia has also made its first step towards fulfilling the obligations of the Stockholm Convention. Moreover, the established management system has contributed for improving the overall state of the environment in the country through offering solution and raising awareness for one specific environmental problem — the PCB. The construction of the interim storage for PCB-containing equipment is the next important step to be made in the process for PCB elimination.

5. Funding

The project was supported by the «Deutsche Gesellschaft fur Technische Zusammenarbeit» (GTZ), the German Federal Ministry for Economic Cooperation and Development (BMZ) and Envio Recycling GmbH & Co. KG.

Ãëàâíàÿ ñòðàíèöà

Ñâåäåíèÿ

îá àâòîðàõ

Barlakoska Ljiljana, sales and project

manager, Envio Recycling GmbH & Co. KG, Kanalstr. 25,

Dortmund, 44147, Germany. Tel. (231) 998-22-75, fax (231)

998-22-02. E-mail

Bergel Helmut, sales and project manager, Envio Recycling GmbH &

Co. KG, Kanalstr. 25, Dortmund, 44147, Germany. E-mail

© Íåçàâèñèìîå

àãåíòñòâî ýêîëîãè÷åñêîé

èíôîðìàöèè

Ïîñëåäíèå èçìåíåíèÿ âíåñåíû 20.09.10