Главная

страница

Сведения об

авторах

Recovering of Sumac Waste as a Source of Polyphenols Using the Novel Processing Technology of Instant Controlled Pressure Drop DIC

Kamal I. M., Allaf K., University of La Rochelle, France

Abstract

Although a substantial amount of works is reported on sumac composition, the literature lacks information on recovering sumac waste as a source of phytochemicals including phenolic compounds. The present work deals with the modification of the technological abilities of this plant regarding the solvent extraction process, through a texturing stage carried out by the instant controlled pressure drop DIC technology. Our study adopted a sequential strategy of the response surface methodology (RSM) as experimental designs in order to firstly chose the DIC processing parameters as independent variables, subsequently, identify the most important effects depending on response parameters, and finally, optimize the whole extraction process. In our case, such an optimization was obtained by simultaneously maximizing the both yields of total phenolics content (TPC), and the antioxidant activity (AOA). The results of the study confirmed that the DIC as a pretreatment could improve the both total phenolic content (65.15 mg GAeq/g db as against 61 mg GAeq/g db for untreated raw material), and the antioxidant activity (reaching up to 125 % compared with untreated raw material). The DIC treatment allowed the activation energy of solvent extraction to become 11.48 kJ/mole as against 17.74 kJ/mole for untreated sumac waste.

Introduction

The dried fruits of sumac commonly used in the Mediterranean and Middle East countries (Gunduz et al., 2010) are one of the richest plants on phenolic compounds of phenolic acids, flavonoids, stilbenes and lignans (Apac et al., 2007). The investigation on polyphenol extraction from natural sources has greatly increased in recent years because of the restricted use of synthetic antioxidants such as butylated hydroxyanisole (BHA) and butylated hydroxytoluene (BHT) in foods (Jayaprakasha et al., 2003).

The improvement of the extraction processes has paid a lot of attention and in-depth knowledge is found in the literature. Although several studies reported the phenolic content of sumac, the literature lacks information about the phenolic content in sumac waste (stems and branches). The objective of the present work deals with studying the effect of the instant controlled pressure drop DIC texturing prior to the extraction of phenolic compounds from sumac waste.

Experimental study

DIC treatment

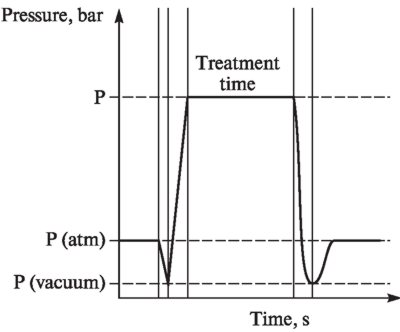

Previous works on DIC food processing at both laboratory and industrial scales showed intensifying kinetics of different processes including drying, extraction and decontamination. DIC even could increase the functional and organoleptic quality of dried foods (Zugali et al., 2010; Kamal et al., 2008). The general DIC pressure — temperature — history profile is shown in Fig. 1.

Fig. 1. DIC Pressure — Temperature —

Time profileSolid-liquid extraction kinetics experiments

The operation of the extraction of the phenolic compounds consisted in mixing dried sumac waste (5 g) with 100 ml of solvent (methanol : water = 70 : 30, v/v) under continuous stirring at (70 ± 0.1) °C. At different time intervals (0.5; 1; 1.5; 2; 2.5; 3; 4; 5; 6; 8; 10; 20; 30; 40; 60 min), sumac material samples were quickly separated from the extract by filtering through a filter paper (Whatman No. 1). The experiments were carried out in triplicate.

Evaluation of the total phenolic content

TPC was calculated by measuring concentration in the extracts using Folin-Ciocalteau spectrophotometric method (Lapornik et al., 2005). The 6-fold-diluted sample (0.5 ml) was added into test tubes followed by 2.5 ml of Folin-Ciocalteau reagent (10 %, v/v). After 30 s to 5 min, an amount of 2 ml of 20 % of sodium carbonate solution was added. All test tubes were caped and shaken for 10 s and put on to incubation in a water bath at 45 °C for 5 min. Absorbance was measured after 30 min at 765 nm (Helios Omega UV/VIS Thermo Scientific Merk and Co. Spectrophotometer) against blank sample.

Blank sample was prepared with water instead of the extract. The measurements were carried out in a duplicate and calculated from the calibration curve obtained with gallic acid used as standard. The results were expressed as mg of Gallic Acid Equivalents (GAE) per g of dry base sumac (mg GAeq/g db).

The antioxidant activity of sumac extracts was measured in terms

of hydrogen donating or radical scavenging ability using the stable DPPH method

(Sanchez-Moreno,

1998).

The sumac extract solution was prepared by diluting 0.5 ml of the crude with 2.5 ml of methanol. The DPPH solution was prepared by diluting 0.004 g in 100 ml of methanol. The diluted extract solution (1 ml) was mixed with the DPPH solution (3 ml) in a bowl. After a 30-minute incubation at room temperature, the reaction solution was examined at 517 nm by using a spectrophotometer. The remaining concentration of DPPH in the reaction medium was calculated with linear regression equation from a calibration curve. The inhibition percentage of the absorbance of DPPH solution was calculated using the following equation:

Inhibition

% =

[(Abst0

-

Abst30)/Abst0]

• 100.

Abst0 was the absorbance of DPPH at time

zero. Abst0 was the absorbance of DPPH at time 30 min of incubation.The percentages of remaining DPPH were plotted against the sample or standard concentrations to obtain the amount of antioxidant necessary to reduce the initial concentration of DPPH.

Experimental design

A preliminary set of experiments allowed identifying the DIC processing saturated steam pressure and heating time as the main variables affecting the extraction efficiency. A central composite design consisting of 11 experimental runs with three replicates at the centre point was then applied (Table).

The experimental design for the DIC processing variables

|

Experimental point |

Saturated steam processing pressure, MPa |

Processing time, s |

|

Maximum |

0.4 |

45 |

|

Minimum |

0.1 |

15 |

|

Central |

0.25 |

30 |

|

DIC No. |

Pressure, MPa |

Time, s |

|

1 |

0.25 |

30 |

|

2 |

0.4 |

15 |

|

3 |

0.1 |

45 |

|

4 |

0.25 |

30 |

|

5 |

0.1 |

30 |

|

6 |

0.25 |

15 |

|

7 |

0.25 |

30 |

|

8 |

0.4 |

30 |

|

9 |

0.1 |

15 |

|

10 |

0.25 |

45 |

|

11 |

0.4 |

45 |

Results and discussion

The extraction of phenolic compounds from sumac waste was optimized by simultaneously maximizing both the TPC yields and AOA using the RSM.

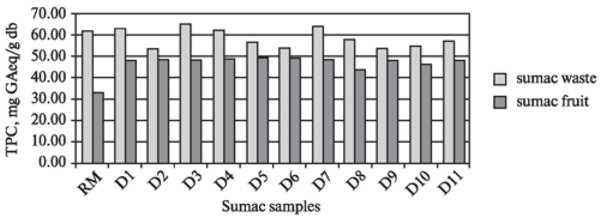

A first amazing result could be found where the yield of TPC extraction from sumac waste was much higher (150 %) than that from sumac fruit (Fig. 2).

Fig. 2. Extraction kinetic profile of sumac fruit and sumac waste

The analysis of TPC extracted from sumac waste raw material and the 11 DIC treated samples (Fig. 3) confirmed that DIC treatment could be an efficient tool to increase the extraction yield of TPC from sumac waste.

Fig. 3. Total phenol content of sumac waste and fruit for raw material and the DIC treated samples

The optimum was computed at P = 0.1 MPa and t = 45 s with a corresponding predict value of TPC = 65.15 mg GAeq/g db, compared to 61.15 mg GAeq/g db for the untreated waste.

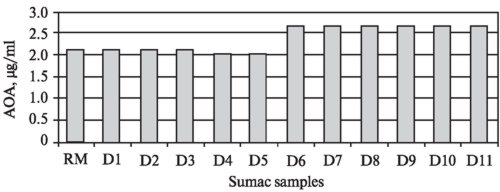

The results of AOA from DPPH assay for sumac waste raw material and the DIC treated samples are shown in Fig. 4.

Fig. 4. Antioxidant activities for untreated raw material and the DIC treated sumac waste

AOA could be improved by up to 126 %. All the extracts possessed strong radical scavenging activity ranged from 2.02 to 2.62 ug/ml compared to BHT (IC50 = 278 ug/ml) and vitamin C (IC50 = 18.15 ug/ml). These results confirm that the sumac waste can be considered as excellent sources of natural antioxidants.

The RSM analysis indicated that both processing time and steam pressure have no significant effects on TPC or AOA. The situation may be attributed to the DIC processing condition ranges used in this study.

On the other hand, the temperature influence on TPC extraction from sumac waste raw material and DIC treated sumac waste was assessed by linearized Arrhenius equation, which gave activation of 17.74 and 11.48 kJ/mole raw material and the DIC treated sumac waste sample, respectively. The results confirm that the extraction for the DIC treated samples requires lower energy than that of the raw material. The phenomenon is very important concerning the time and energy conservation.

Acknowledgements

The authors acknowledge FEDER funds and la Delegation Rgionale a la Recherche et a la Technologie (DRRT) — France, for the financial support of this research.

Kamal Ibtisam,

Prof., Laboratory of Transfer Phenomena and Instantaneity in Agro-Industry and

Building LEPTIAB, University of La Rochelle, Pôle Sciences et Technologie Bât.

Marie Curie – Av. Michel Crépeau 17000, La Rochelle, France. Tel. (648)

21-52-74, fax (546) 45-86-16.

E-mail

Allaf K.,

Laboratory of Transfer Phenomena and Instantaneity in Agro-Industry and Building

LEPTIAB, University of La Rochelle, Pôle Sciences et Technologie Bât. Marie

Curie – Av. Michel Crépeau 17000, La Rochelle, France.

E-mail

© Независимое

агентство экологической

информации

Последние изменения внесены 29.03.11